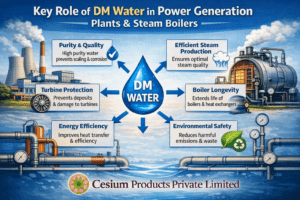

KEY ROLE OF DM WATER (DI) IN POWER PLANT GENERATION AND STEAM BOILERS

Water quality plays a critical role in power generation plants and steam boilers. One of the most important most important types of water used in these systems is DM water (Demineralized Water). It helps protect equipment, improve efficiency, and ensure safe operations.

Let us understand why DM (DI) water is essential and how it supports power plants and boiler systems.

What is DM (DI) Water?

DM (DI) water is water from which all dissolved minerals and salts are removed using ion-exchange processes.

As a result, DM (DI) water contains very low conductivity and zero hardness, making it ideal for high-temperature and high-pressure applications.

https://thewatersolutions.net/dm-water-secrets-what-its-used-for-why/

https://thewatersolutions.net/how-long-can-dm-di-water-be-stored-safely/

Why Water Quality Matters in Power Plants?

Power generation plants use boilers to produce steam. This steam drives turbines to generate electricity.

However, ordinary water contains salts and minerals. When heated, these impurities can cause serious damage.

Therefore, using DM (DI) water becomes necessary.

Key Role of DM (Distilled) Water in Steam Boilers

Prevents Scale Formation

First of all, DM (Distilled) water does not contain calcium or magnesium. Because of this, scale does not form on boiler tubes

As a result, heat transfer remains efficient and fuel consumption stays low.

Reduces Corrosion

In addition, dissolved salts can cause corrosion in boilers and pipelines.

DM (Distilled) water helps reduce corrosion, which increases the life of equipment.

Improves Boiler Efficiency

When scale and corrosion are minimized, boilers operate smoothly.

Consequently, steam generation becomes more efficient and energy losses are reduced.

Importance of DM (DI) Water in Power Generation Plants

Protects Turbines and Heat Exchangers

DM water prevents deposits on turbine blades and heat exchangers.

This ensures stable performance and reduced maintenance shutdowns.

Maintains Steam Purity

Pure steam is critical in power plants.

DM (DI) water ensures high steam purity, which protects turbines and improves power output.

Supports High-Pressure Operations

Power plants operate at very high pressure and temperature.

DM (Distilled) water is suitable for such conditions because it does not leave residues.

DM (DI) Water Conductivity and Boiler Safety

DM (DI) water typically has low conductivity, usually below 10µS/cm.

Low conductivity indicates fewer ions in the water.

This helps prevent electrical and chemical damage inside boilers and plant systems.

DM (DI) Water v/s Normal Water in Boilers

Parameter Normal water DM (DI) Water

Mineral content High Almost zero

Scale formation Yes No

Corrosion risk High Very low

Boiler efficiency Reduced Improved

Maintenance cost High Low

Economic Benefits of Using DM (Distilled) Water

Although DM (Distilled) water treatment has an initial cost, it offers long-term savings.

For example:

- Less equipment damage

- Lower maintenance costs

- Improved fuel efficiency

- Longer plant life

Thus, DM (Distilled) water is cost-effective in the long run.

CONCLUSION

In conclusion, DM (DI) water plays a key role in power generation plants and steam boilers. It prevents scale and corrosion, improves efficiency, and protects critical equipment. By using DM (DI) water, power plants can operate safely, efficiently, and economically.

Frequently Asked Questions (FAQs):

Q1. What is DM (DI) water used for in power plants?

DM (DI) water is used in boilers, turbines, and cooling systems to prevent scaling and corrosion.

Q2. Why can’t normal water be used in steam boilers?

Normal water contains minerals that form scale and cause corrosion when heated.

Q3. Is DM (DI) water mandatory for high-pressure boilers?

Yes, high-pressure boilers require DM (DI) water to ensure safety and efficiency.

Q4. What happens if DM (DI) water is not used?

Boilers may suffer from scale build-up, corrosion, reduced efficiency, and frequent breakdowns.

Q5. How often should DM (DI) water quality be checked?

DM (DI) water quality should be monitored regularly using conductivity meters.

“For any queries, please contact us using the email ID provided.”

EMAIL – [email protected]