HOW DISTILLED WATER IS EFFECTIVE IN CENTRALIZED COOLING

Centralized cooling systems are commonly used in large buildings such as offices, hospitals, malls, hotels, and industries. These systems help maintain a comfortable indoor temperature by cooling the entire building from one central unit.

Distilled Water plays a vital role in various Industries, including medical applications, Laboratories, household uses, personal hygiene, automotive applications, cosmetic products, and food and beverages. Among these applications, distilled water is also widely used in centralized cooling system in air conditioning.

Before Understanding how distilled water is effective in a centralized cooling system, let us first understand what a centralized cooling system is.

What Is a Centralized Cooling System?

A Centralized cooling system is an air-conditioning system where cooling is where cooling is produced at one central location and then distributed to different rooms or areas through ducts.

Instead of using separate air conditioners for each room, one powerful system cools the entire building. This helps in better temperature control, energy savings, and easy maintenance.

Why Is Distilled Water Used in Centralized Cooling Systems?

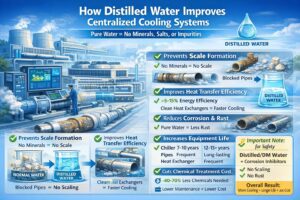

Distilled water is water that has been purified by removing minerals, salts, and impurities. This makes it ideal for use in cooling systems.

- Prevents Scale Formation

Normal tap water contains minerals like calcium and magnesium. These minerals can form scale inside pipes, chillers, and cooling coils. Distilled water prevents this problem.

- Reduces Corrosion

Impurities in water can cause corrosion in metal parts. Distilled water is free from these impurities, helping to protect equipment and increase its life.

- Improves Heat Transfer

Pure water allows better heat exchange, making the cooling process more efficient.

- Low Maintenance

Using distilled water reduces frequent cleaning, breakdowns, and maintenance costs.

- Increases System Life

Since there is less scaling and corrosion, the overall lifespan of the centralized cooling system is improved.

Normal Water v/s Distilled Water in Centralized Cooling System

The type of water used in a centralized cooling system directly affects its performance and lifespan.

Normal water such as tap water, bore water, or partially treated water contains minerals like calcium and magnesium. These minerals slowly form scale inside pipes and cooling coils, reducing efficiency.

Distilled water, on the other hand, is free from minerals and impurities, making it ideal for long-term cooling applications.

Parameter Normal Water Distilled Water

Mineral content High Nil

Scale formation Yes No

Common risk High Very low

Cooling efficiency Reduces over time remains high

Chemical requirement High Very low

Maintenance cost High Low

System life Shorter Longer

Although normal water may appear economical initially, it increases maintenance cost and reduces system efficiency over time. Distilled water provides better cooling, cleaner operation, and longer system life.

Applications of Centralized Cooling Systems Using Distilled Water

- Commercial buildings

- Hospitals and laboratories

- Shopping malls

- Hotels

- Industrial plants

- Data centers

Conclusion

Centralized cooling systems are an efficient solution for cooling large buildings. Using distilled water in these systems helps prevent scaling, corrosion, and performance loss. As a result, the system delivers consistent cooling, consumes less energy, and requires less maintenance.

Distilled water is therefore a smart and reliable choice for centralized cooling systems.

Frequently Asked Questions (FAQs):

Q1. What type of water is best for centralized cooling systems?

Distilled water is the best choice for centralized cooling systems because it does not contain minerals or impurities that cause scaling and corrosion.

Q2. Can normal tap water be used in a centralized cooling system?

Tap water can be used initially, but it contains minerals that cause scale formation, pipe blockage, and corrosion overtime. This reduces cooling efficiency and increases maintenance cost.

Q3. Why does scaling occur in cooling systems?

Scaling occurs due to minerals like calcium and magnesium present in normal water. When water is heated or circulated continuously, these minerals deposit inside pipes and cooling coils.

Q4 How does distilled water improve cooling efficiency?

Distilled water allows better heat transfer because it is free from minerals and impurities. This helps the system cool faster and work more efficiently.

Q5 Does distilled water reduce corrosion in cooling systems?

Yes. Since distilled water is free from salts and contaminants, it significantly reduces corrosion of metal components such as pipes, chillers, and heat exchangers.

Q6 Is chemical treatment required when using distilled water?

Chemical treatment is minimal when distilled water is used because there is no scale formation and very low corrosion risk.

Q7 Can RO water be used instead of distilled water?

RO water is better than tap water but may still contain small amount of minerals. Distilled water is more suitable for centralized cooling systems where high purity is required.

Q8 Does using distilled water increase the life of the cooling system?

Yes. By preventing scale and corrosion, distilled water helps extend the life of chillers, pipes, and other cooling system components.