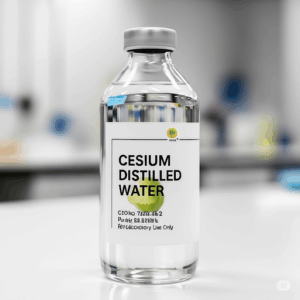

Cesium Distilled water is critical for cleaning and sterilization in the pharma industry because any contamination in cleaning water can directly compromise product quality, sterility, and regulatory compliance.

Here’s why it’s so important

- Zero Residue After Cleaning and comparison

- Problem with normal water: Tap or hard water contains calcium, magnesium, silica, and other dissolved solids that can leave white spots, scales, or films on stainless steel tanks, glassware, and instruments.

- Distilled water advantage: Being free from minerals and salts, it dries without residue, ensuring surfaces remain chemically inert and clean.

- Prevents Re-Contamination safety first

- After CIP (Clean-In-Place) and SIP (Sterilize-In-Place), the final rinse must not introduce new contaminants.

- Distilled water is microbe-free and low in total organic carbon (TOC), so it prevents bacterial or endotoxin introduction during the last rinse.

- Maintains Sterility in Autoclaves

- Autoclaves use steam for sterilization. If the feed water contains minerals:

- It causes scaling in the heating elements and steam lines.

- Reduces sterilization efficiency.

- Distilled water produces pure steam with consistent temperature and pressure, ensuring proper sterilization cycles.

- Essential for Cleaning Sensitive Equipment

- Instruments like HPLC, GC, FTIR, incubators, and biosafety cabinets require residue-free cleaning.

- Even trace minerals from non-distilled water can:

- Damage sensitive parts.

- Alter analytical readings.

- Distilled water preserves accuracy and extends equipment life.

- Prevents Cross-Contamination Between Batches

- In pharma manufacturing, even a microscopic carryover of active pharmaceutical ingredients (APIs) can cause product mix-ups.

- Distilled water ensures that cleaning removes all traces of previous batch ingredients without leaving behind its own contaminants.

- Regulatory Mandate

- WHO, US FDA, and GMP guidelines recommend purified or distilled water for final rinsing in:

- Sterile product manufacturing areas

- Cleanroom cleaning

- Laboratory glassware

- Using anything less can result in audit failures and product recalls.

Example in a Sterilization Workflow

- Pre-wash with regular water to remove bulk dirt.

- Wash with detergent + purified water.

- Final rinse with Cesium distilled water Bangalore to ensure no residues or microbial load.

- Steam sterilize (autoclave) using distilled water feed.